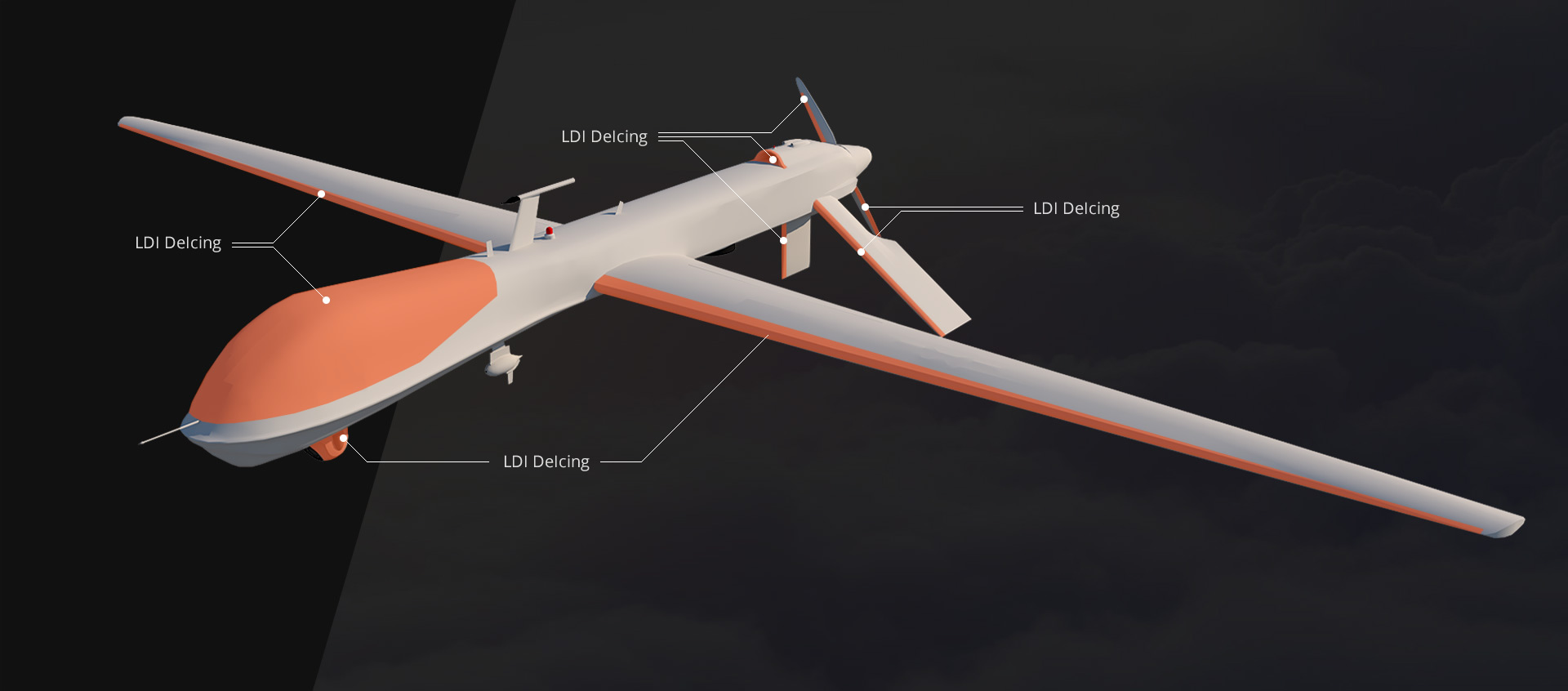

Fixed WingIce Protection Systems

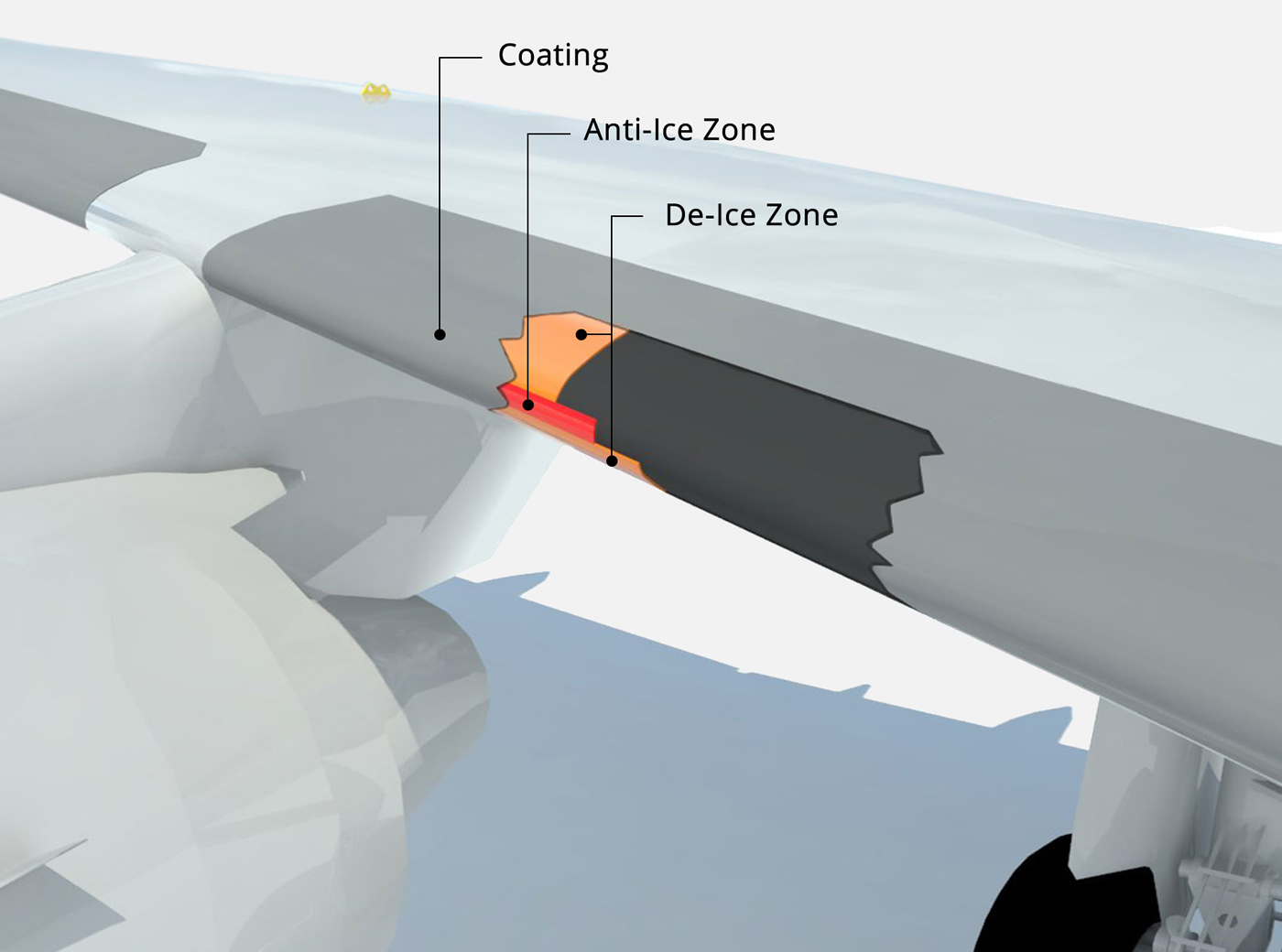

LDI- Ice Protection Systems are applicable to various parts of the aircraft. The simplest and most durable solution for Ice Protection on leading edges of wings, empennage, nacelle, air-intakes, propellers, radomes and all other areas where it is necessary.

High efficiency – low energy requirement

LDI-ETIPS -

Thermo Electric Ice Protection System

LDI-ETIPS is the most robust, light and efficient electro thermal Ice-Protection-System available today. In house design, development and production of customized Ice Protection Systems guarantee best performance and the highest aerodynamic properties. The use of self-regulating heater elements that can withstand an electrical load of up to 77 watts / inch2 (12 W / cm2) and do not form dangerous sources of fire after damage, but continue to function, offer a new safety standard. As a result, the LDI-ETIPS ice protection systems can not only be used on metal, but are also very suitable for implementation in composite structures.

Improved

Aerodynamics

IMPROVED AIRPLANE PERFORMANCE

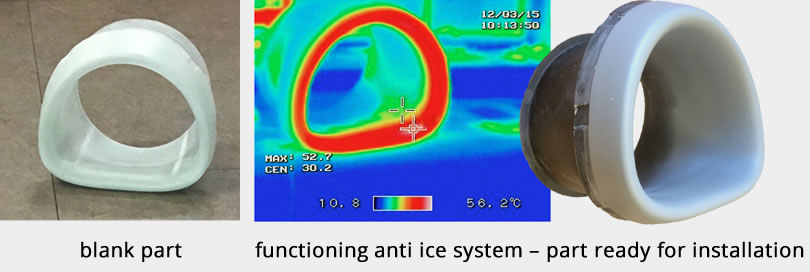

LDI-ETIPS is suitable for all kind of aircraft and ideal for ice protection on Leading Edges of Wings, Stabilizers, Air Intakes, Rotors, Propellers and all areas where best ice protection performance is required.

Test Flights show significant airplane performance improvement over same Propeller with conventional Ice Protection System

Low energy consumption - high reliability

LDI-EMIPS -

Electro Mechanical Ice Protection Systems

LDI-EMIPS is a de-icing system that was developed for aircraft and flying platforms that can only provide very little electrical power for ice protection or in case any thermal footprint must be avoided. LDI-EMIPS is a system which is able to shake off ice mechanically. In house design, development and production of customized Ice Protection Systems guarantee best performance and the highest aerodynamic quality. Compared to conventional pneumatic systems LDI-EMIPS has highly improved resistance against erosion and features much better aerodynamic properties which improve airplane performance over all. In house design, development and production of customized Ice Protection Systems guarantee best performance and the highest aerodynamic quality

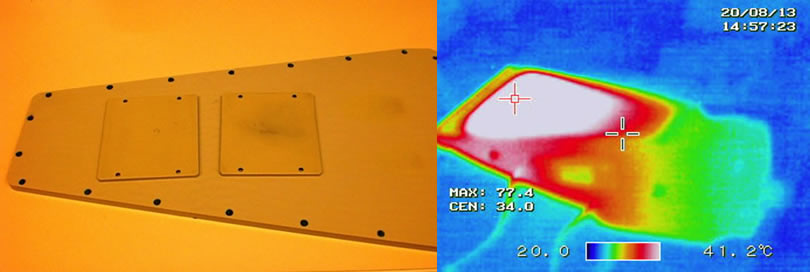

LDI-EMIPS may be designed for ice protection of metal or composite leading edges of wings, stabilizers, air intakes, and other areas where ice protection is required and may be combined with LDI-ETIPS if required.

LDI-EMIPS de-ice cycle on aircraft leading edge

Propeller

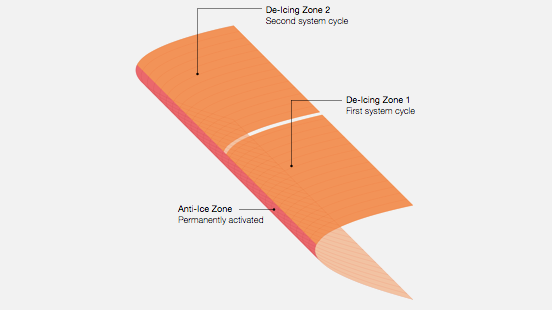

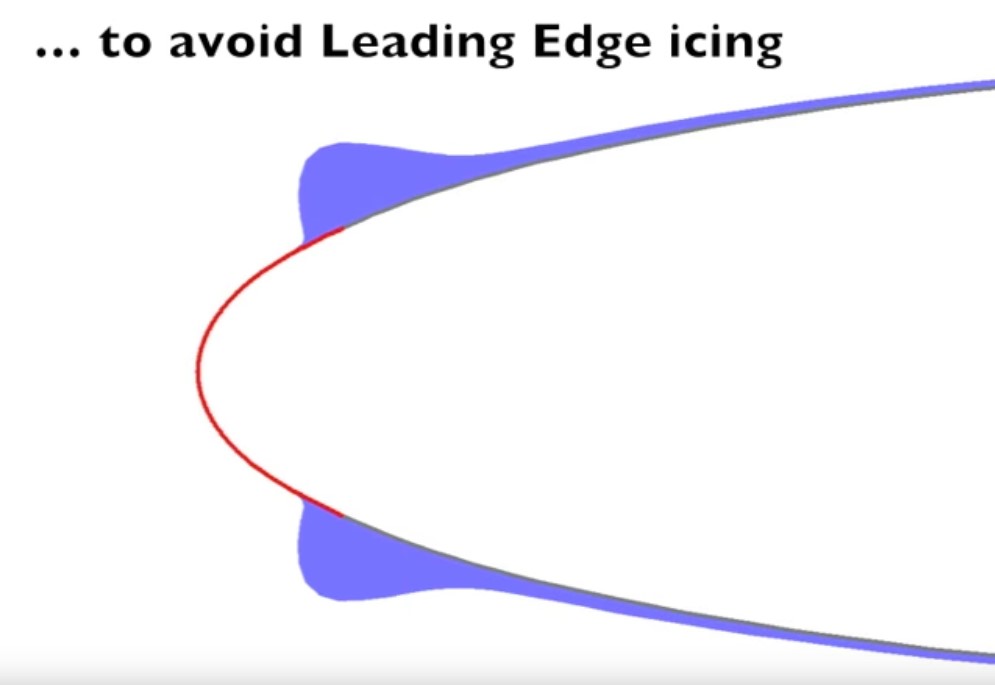

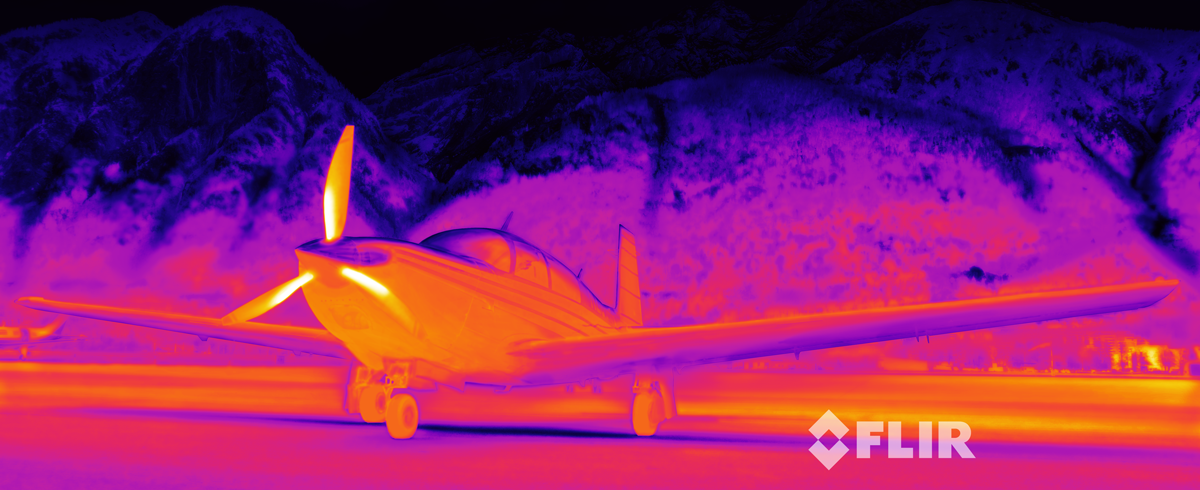

CLEAN (integrated) Ice Protection

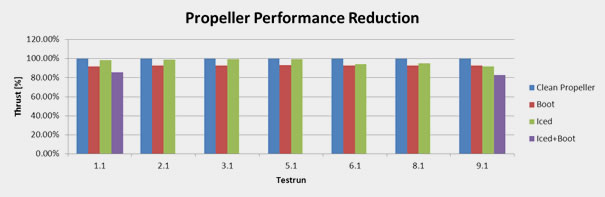

Conventional de-icing boots create an aerodynamically unclean surface on the propeller leading edge, resulting in a permanent loss in actual airplane performance. These disadvantages do not apply to LDI integrated propeller de-icing systems. Highly damage tolerant and integrated into the propeller structure, our systems guarantee improved airplane performance with lower energy consumption.

IncreasedPerformance

Conventional Ice Protection Systems degrade Propeller Performance significantely

Performance of propeller with de-ice boots versus LDI integrated de-ice System.

Watch on Youtube. Download PDF Propeller Test Flight Comparison

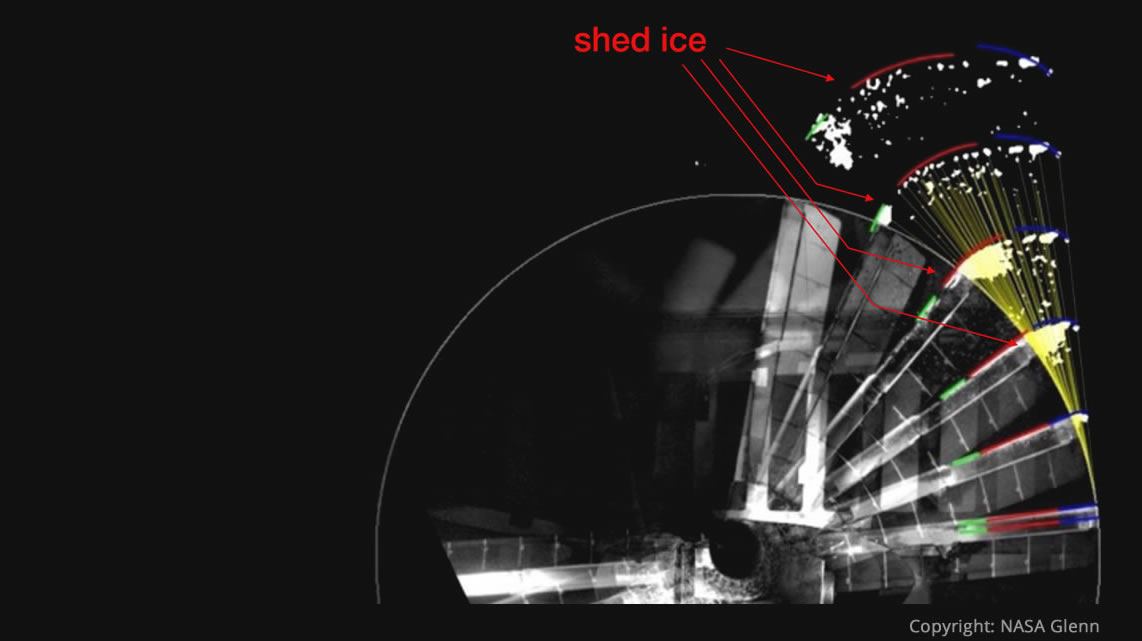

RISP

Rotor Ice Shed Protection

Shed ice from rotor blades is a ballistic concern for:

- Tilt Rotor Aircraft - may damage components on the fuselage

- Engines - may cause internal damage or ”flame out”

- Wind Turbines - danger for humans and animals

Ice Protection on other parts

LDI Ice Protection Systems can be designed to be applied or implemented on various shapes and materials – no matter if composite or metal. Systems which are light weight, robust, simple in handling and without any aerodynamic panelty.

Ice Protection system

Pitot strut

Tests in Icing wind tunnel show Ice accreation on pitot tube extension strut in a very short time without Ice protection system – permantely ice free with LDI ice protection system even in servere Icing conditiones

Technology

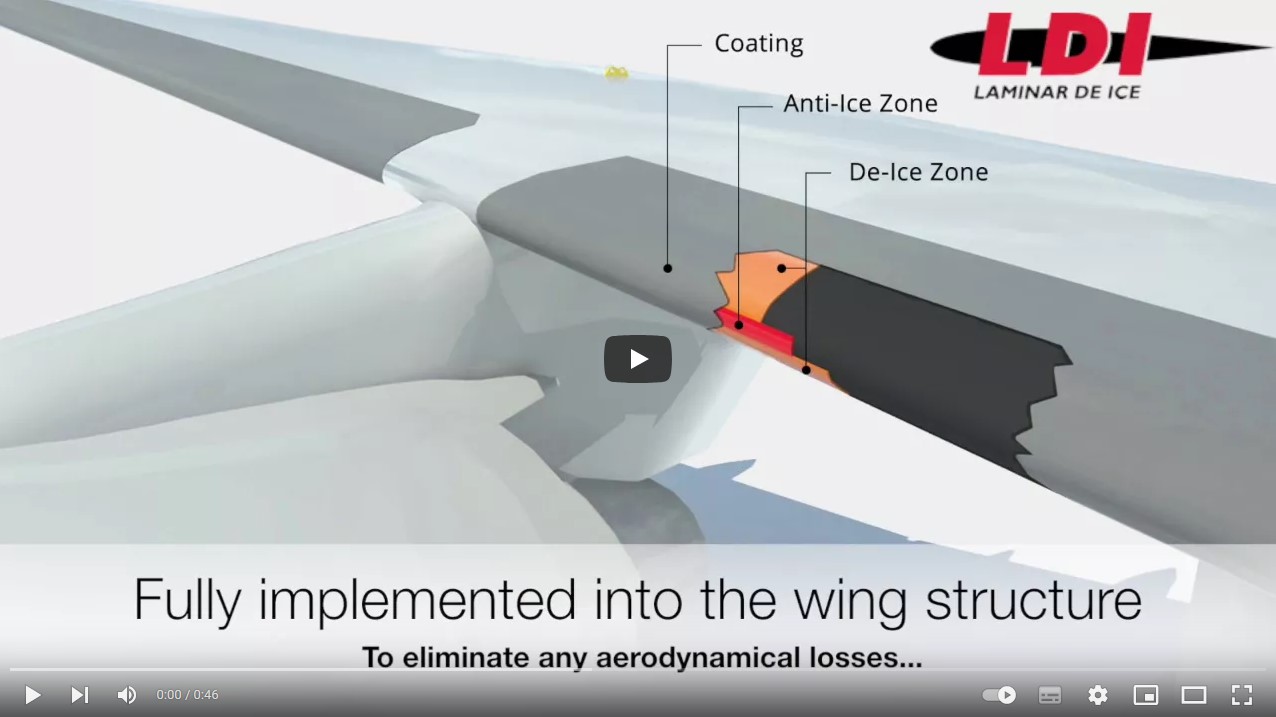

New Generation De-Ice Systems

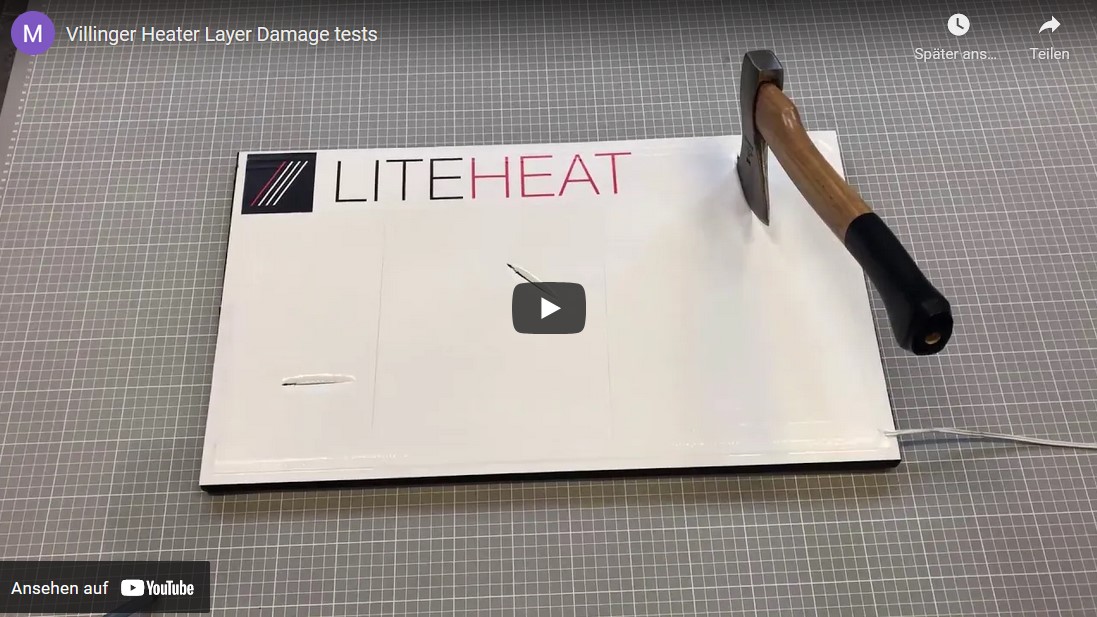

Over the past several years, Villinger R&D has developed proprietary, elastic semi-conductive polymers that can be applied as a thin coating (< 0.2mm) to a variety of parts and components, yielding a heat-able layer with a surface density of approximately 150 g/m2 or less. The coating is heated electrically using either AC or DC voltage and has a positive temperature coefficient (PTC), which yields a coating that is temperature self-limiting and will not experience damaging “hot spots” encountered by traditional resistive heaters. The coating sheet resistances can also be chemically tailored to obtain values ranging over several orders of magnitude depending on the requirements of the application.

The coatings are extremely damage tolerant and can readily continue to operate after being punctured repeatedly. Finally, voltage can be applied across the entire surface using flexible, low profile electrical buses on either side of the coated area, enabling extremely simple wiring configurations that can be laid out in a multitude of geometries to fine tune desired power densities.

Heat-able coatings developed by Villinger R&D

- Have low energy consumption

- Are easily applicable as a paint on 3D and twisted surfaces

- Will not affect the aerodynamics of the vehicle, as they can be integrated fully into composite structures

- Are thin and lightweight

- Are easily applicable to a variety of substrate materials with excellent adhesion properties

- Will continue to operate despite damage and can be readily reapplied if damage occurs

- Will not affect the integrity of structural components

- Employ a self-controlling heating technology that provides even temperature over the complete surface covered, preventing “hot spots” typical of resistive heaters

- Are ideal for use in composite structures due to distributed heating with no “hot spots” that may cause damage

- Are elastic and can sustain elongations and vibrations representative of rotorcraft operation

Specifications of Villinger’s heat-able coatings:

- System thickness: < 2/10 mm

- Overall System weight: < 150 g/m2

- Temperature: (active / passive) up to 180° Celsius

- max. Power Density: 12 W / cm² / 77 W / inch²

- Variable Voltages: (from 6V up to 690V AC or DC)

- Heating Systems can operate with and without ECU (Electronic Control Unit)

The main features of Villinger’s heat-able coatings are therefore:

- Safe by design

- High damage tolerance

- Improved flying performance

- Fuel and energy savings

- Performance superior to state of the art technology (like de-icer pads)

- Low power consumption

- High environmental and structural durability

- Proven performance

- Flexible and easy application

LDI systems are safe by design

Safety

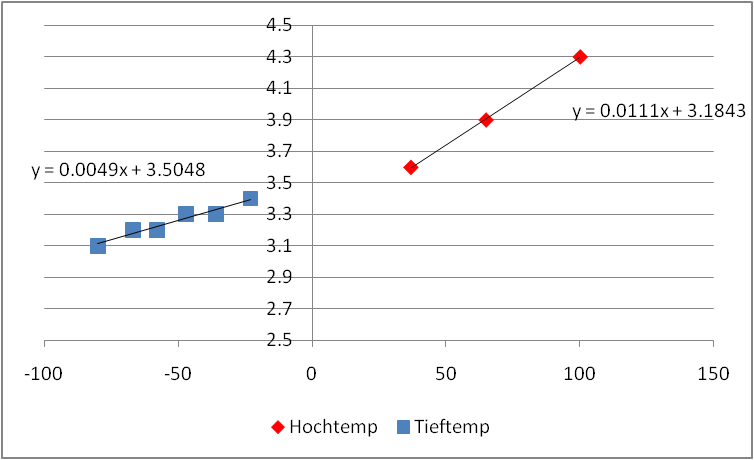

An extremely useful property is that LDI uses Villinger’s heat-able coatings which have a positive temperature coefficient (PTC). In such materials the electrical resistance increases with increasing temperature. As a result, a PTC coating can be designed to reach a maximum temperature for a given input voltage, since at some point any further increase in temperature would be met with greater electrical resistance. As a result, PTC coatings are temperature self- limiting and prevent heater failure due to “hot spots” that can quickly develop with conventional heaters. Villinger coatings also exhibit smooth, distributed heating over the entire energized zone. Because Villinger coatings are temperature self-limiting, on many occassions there is no need to thermal sensing which may be required using conventional de-icer pads, thus further reducing system complexity. It should also be noted that Villinger designs the polymers to have only mild resistance changes with varying ambient temperature, primarily to ensure sufficient resistance at lower temperatures to prevent extreme power draw by the system when initially activated.

PTC characteristics of Villinger’s heat-able coatings are tuned to operate at low or high temperatures in order to reduce energy consumption when initially activated (X axis: temperature, Y axis: resistance in Ohms).

The heat-able Villinger coatings have in-built PTC characteristics, which protect them from overheating, runaway effects and development of hot spots.