Wind Energy Ice Protection

Since the world’s best wind regions are often located on mountains and/or cold climate areas, more and more wind turbines have to be placed where rotor blade icing is an issue. The most important points for customers are reliability and profitability, which can only be reached when the turbines downtime is reduced to a minimum.

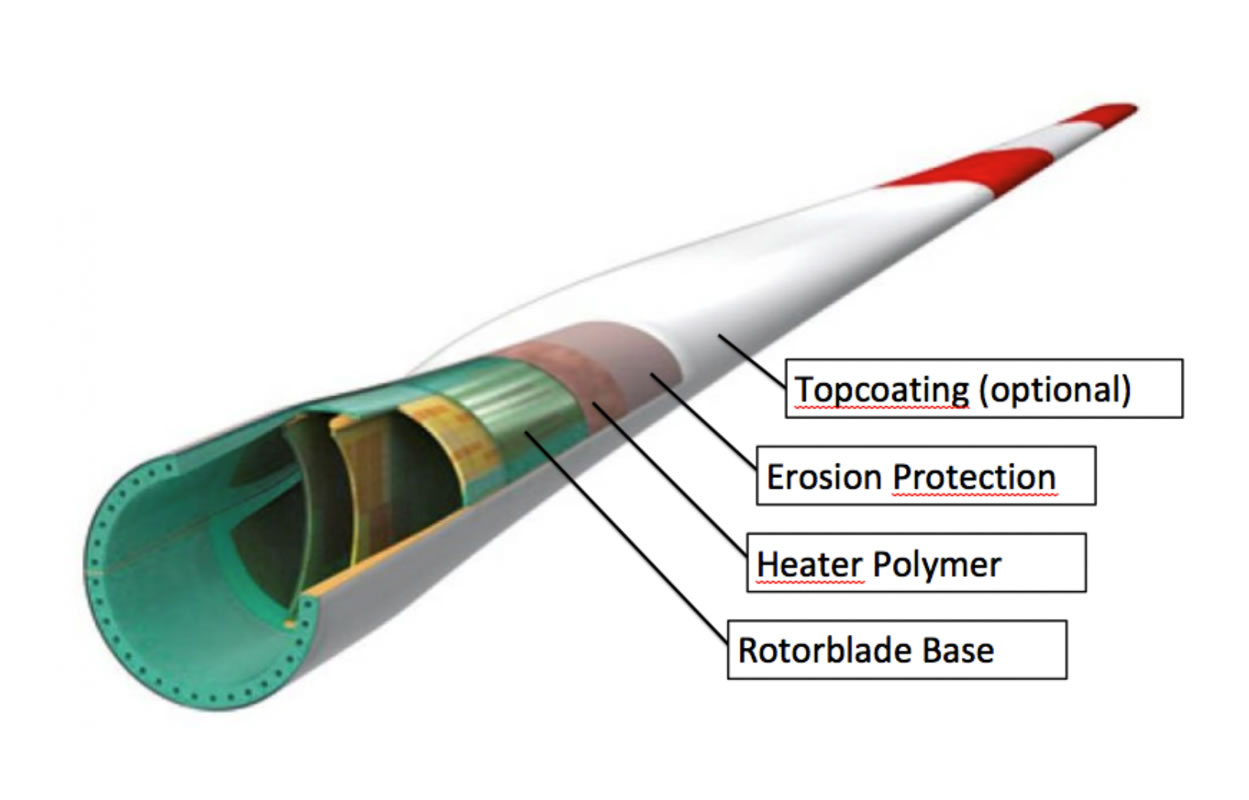

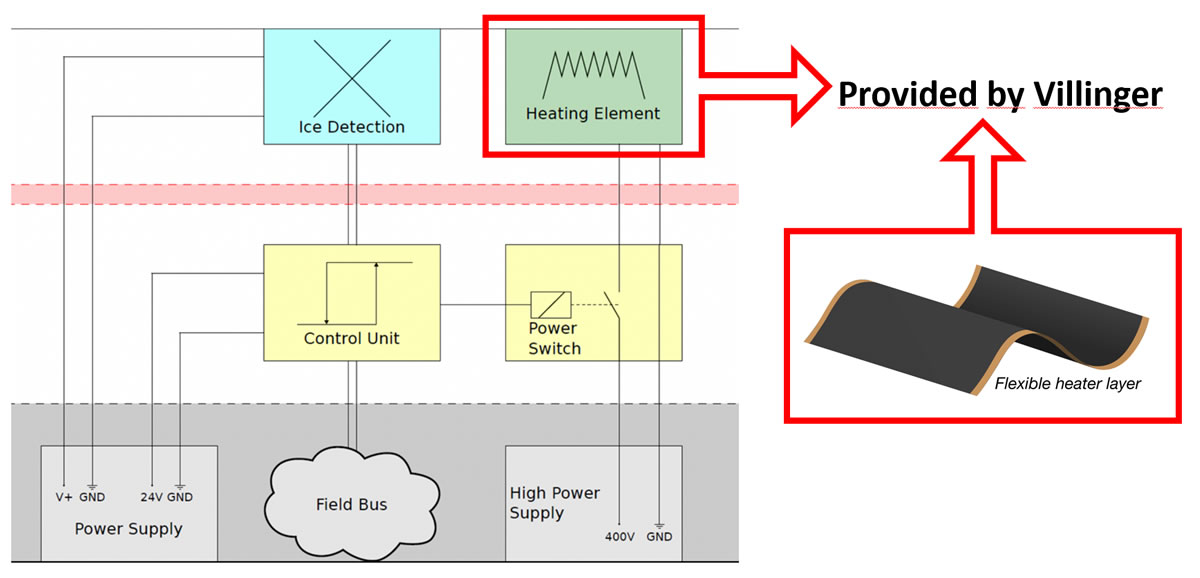

Our business is to „fight the ice“ and to keep the turbine producing energy even in and after severe weather conditions in cold climates. The Villinger “LDI” Ice Protection System may be integrated during the manufacturing process of new blades. The system offers the most robust and energy efficient wind turbine ice protection system available today.

RISP

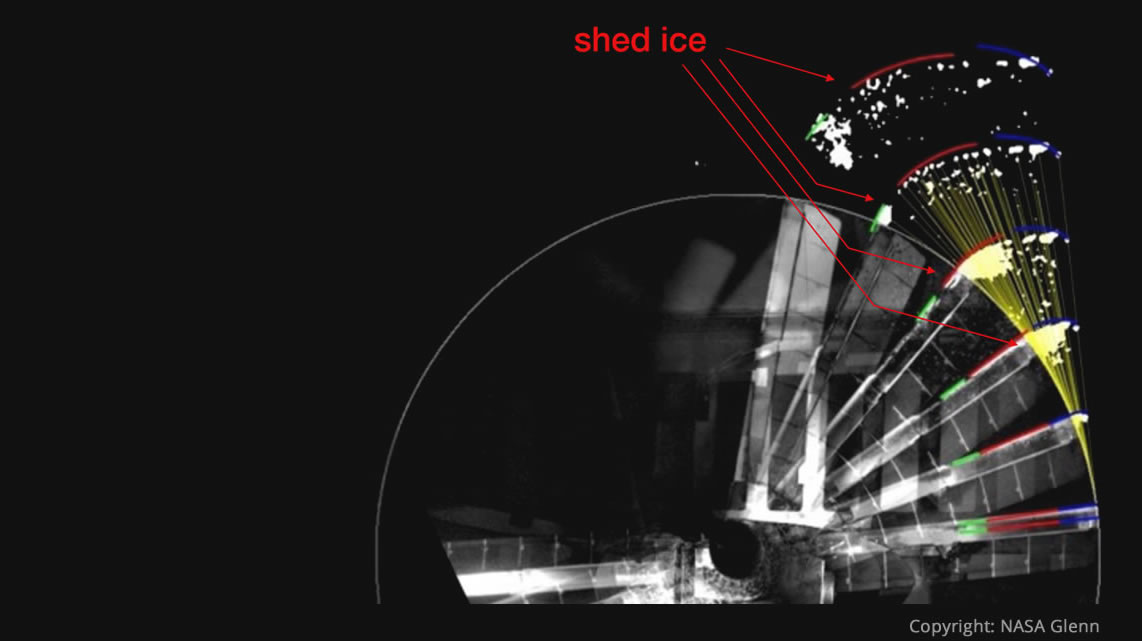

Rotor Ice Shed Protection

Shed ice from rotor blades is a ballistic concern for:

- Tilt Rotor Aircraft - may damage components on the fuselage

- Engines - may cause internal damage or ”flame out”

- Wind Turbines - danger for humans and animals

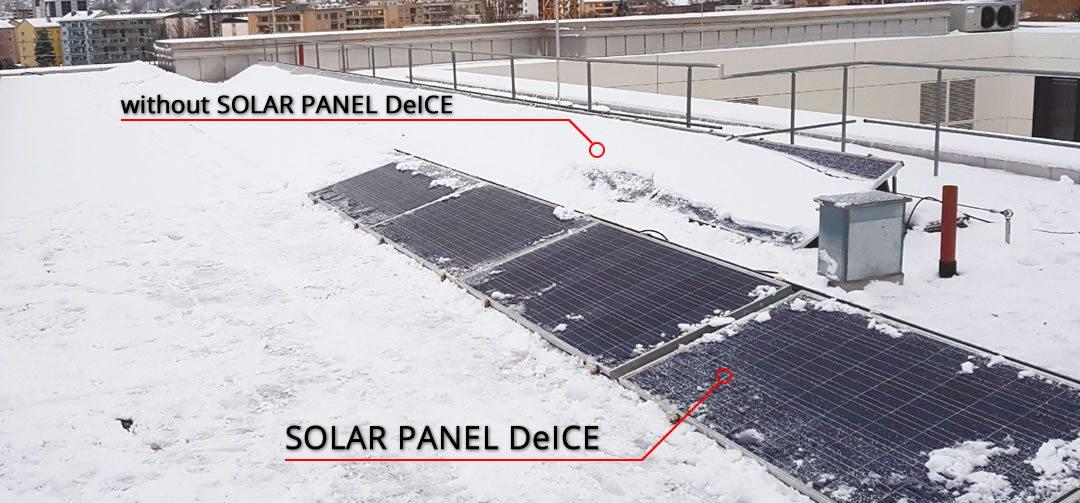

Solar Panel DeIce

SOLAR-DEICE is a highly effective de-icing system, specially developed for photovoltaic and solar panels.

The SOLAR-DEICE de-icing system allows to keep photovoltaic / solar modules snow and ice free even in severe winter conditions, ensuring both reliability and maximum yield of your photovoltaic / solar system.

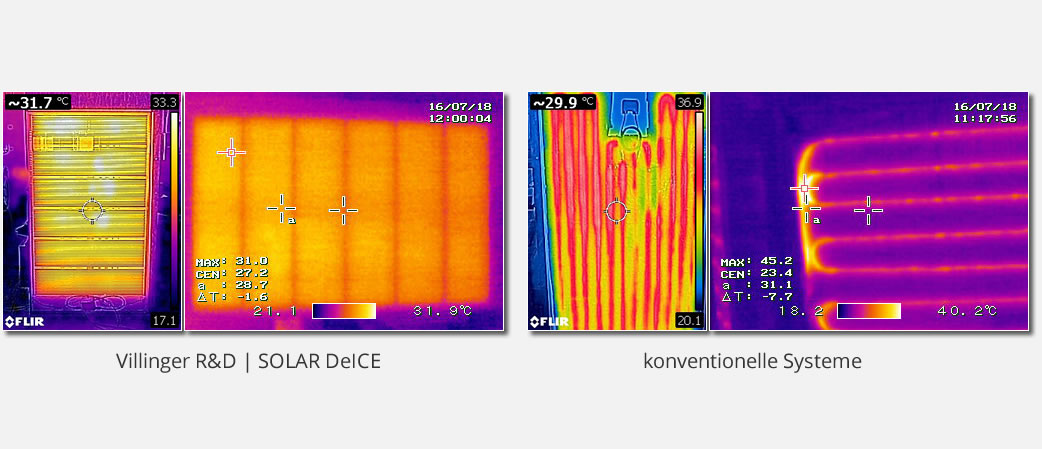

Technology

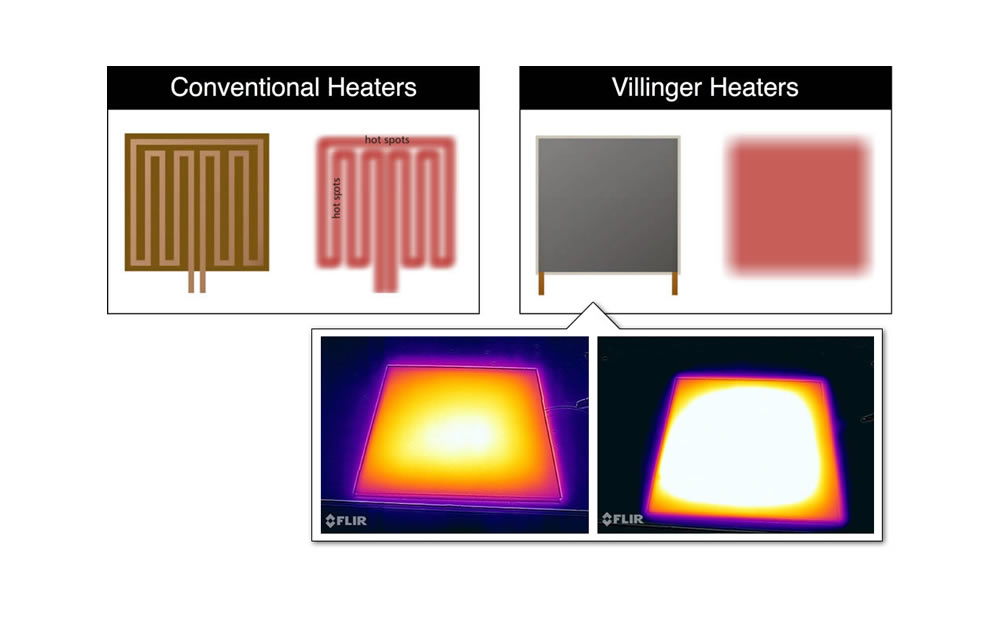

Compared to conventional PV heating systems, Solar DeIce offers homogeneous heat generation without hotspots, which can damage photovoltaic cells.

SOLAR-DEICE is easy to assemble by sticking it to the back of the panels. SOLAR-DEICE is suitable for both the private and commercial sector.

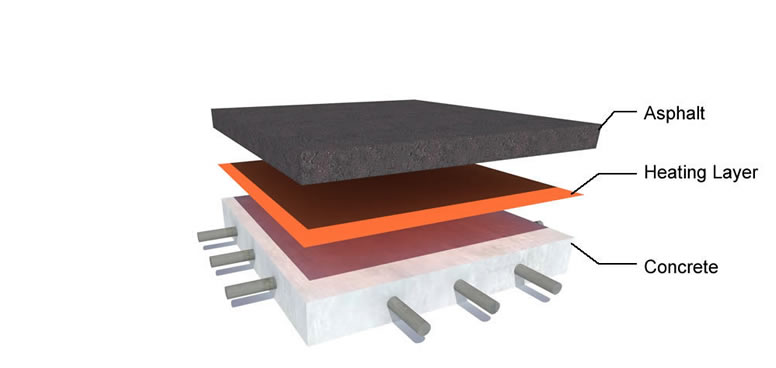

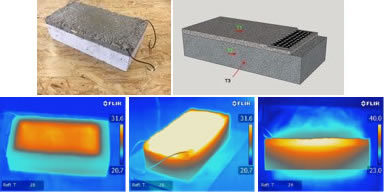

Floor DeIcing

Ice build-up on outdoor floors can be a major safety hazard and may lead to fatal accidents. Floor de-icing using conventional heating methods is characterized by complex build-up, high installation costs and require a lot of maintenance. The Villinger floor de-icing system is integrated under the top concrete layer, providing enough heat to the surface in order to keep walk-, and driveways clear of ice and snow. This self-regulating heating system can be integrated into almost any floor type and needs only a fraction of the energy, needed by conventional systems.

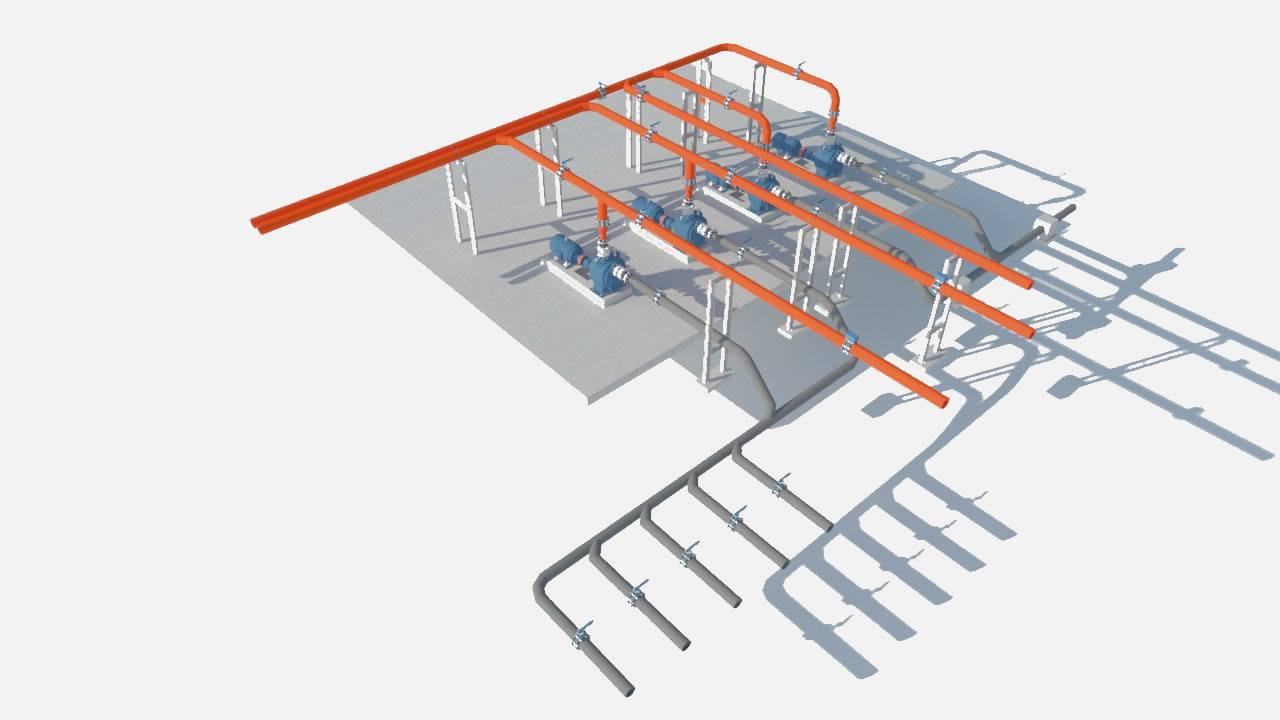

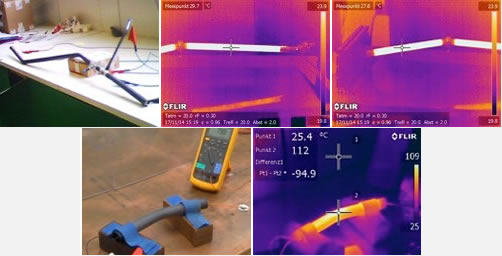

Water Pipe Heating

Villinger pipe heating systems are used for different kinds of pipes. The heater layer is applied directly onto the outer pipe surface, providing effective heating-, and de-icing capabilities. Due to their low weight and simple build-up, these systems are mainly used for drainage and wastewater systems in the Aviation industry.

LED Lamps Heating

Since LED lamps produce significantly less waste heat than conventional light bulbs, their suitability for outdoor lighting applications is limited, due to their sensitivity to cold temperatures. Villinger LED heating systems expand the application range of LED lamps drastically and already enabled the use of LED lamps for railway-, and airport signal lighting, often operating under extreme weather conditions.

Villinger Heating Technology

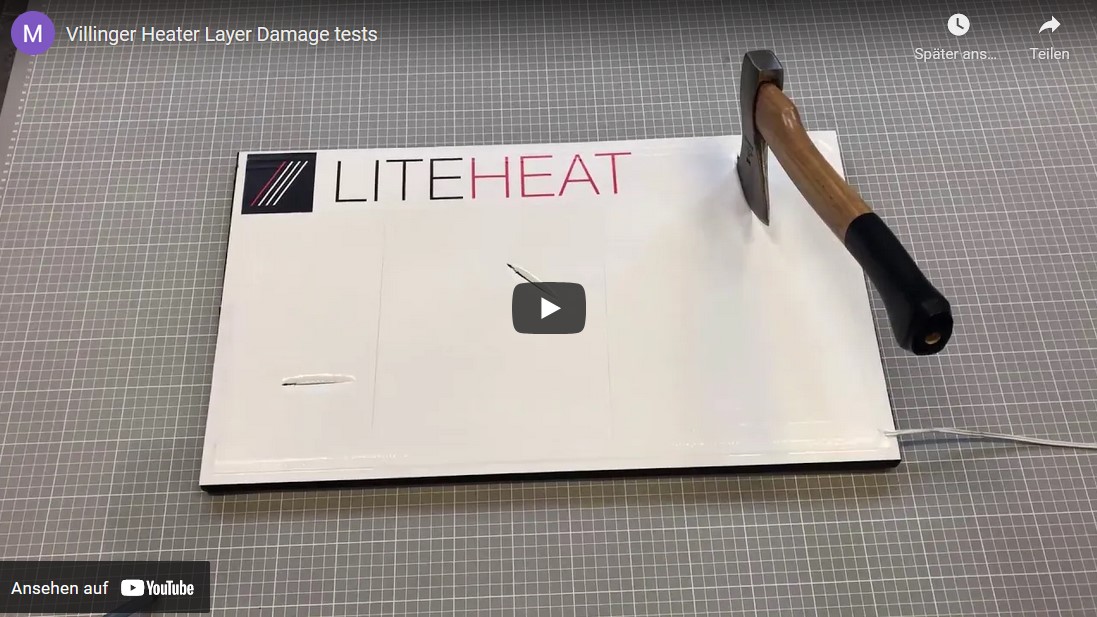

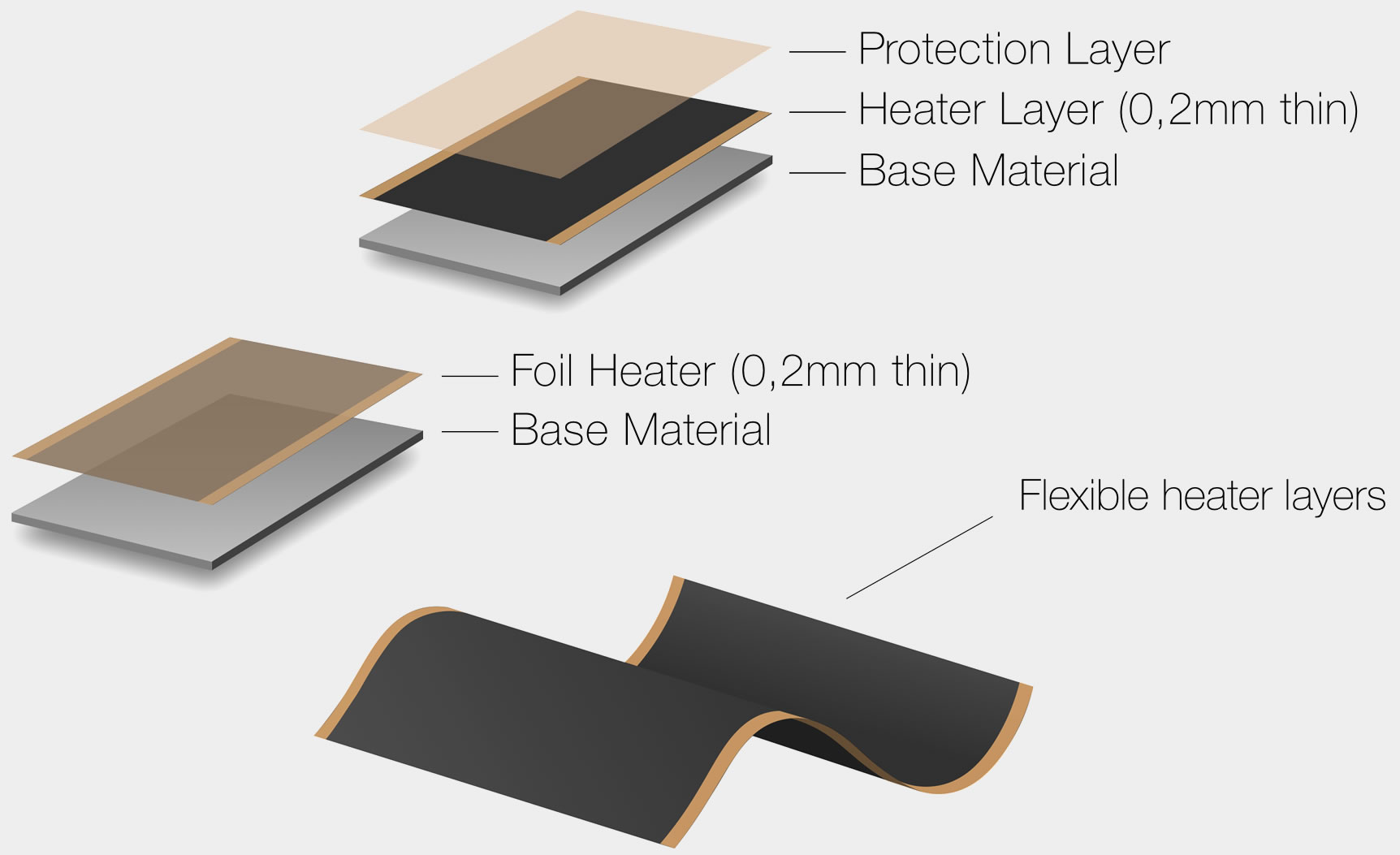

We have developed electrically heated, semi-conductive coatings that are applicable on various surfaces as an ultra-thin heater layer (<0,2mm thickness, <150g/m2). When voltage is applied, the heater layer provides an even, full-face heat build-up and emits infrared radiation heat. Matching the exact 3D shape of the part and only adding 0,2mm in thickness, our heater layer forms the most versatile heating technology available.

Heater Design

The Villinger heating technology is characterized by great versatility and easy application, which allows us to put heat directly exactly where it is needed. Depending on application needs and/or customer requirements, the heater layer can be applied onto almost any desired base material either directly, or as a foil heater. Where conventional heating technologies fail is where we step in to solve the problem.

Self- Regulation & System Safety

Villinger R&D systems are safe by design:

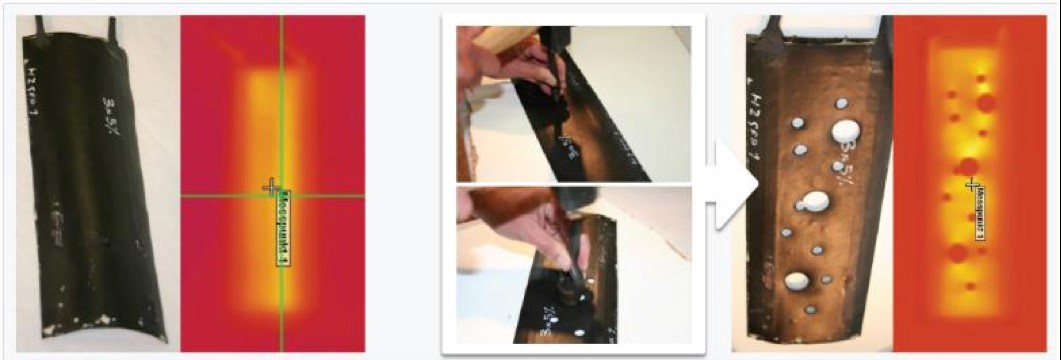

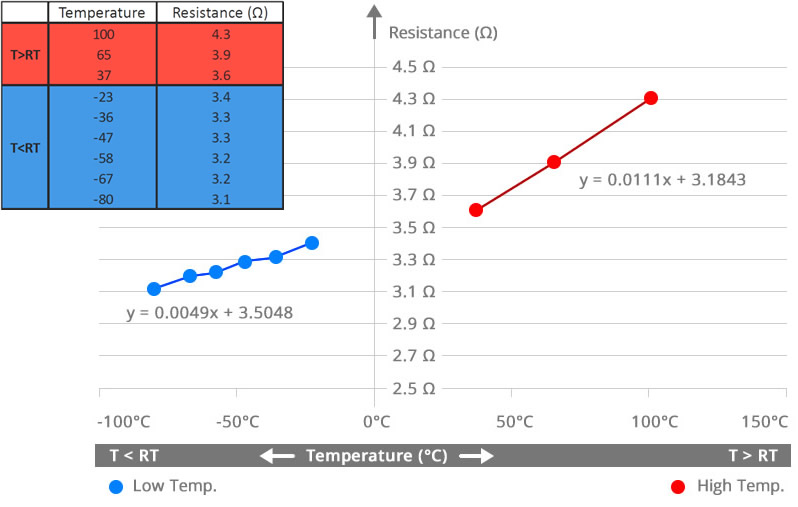

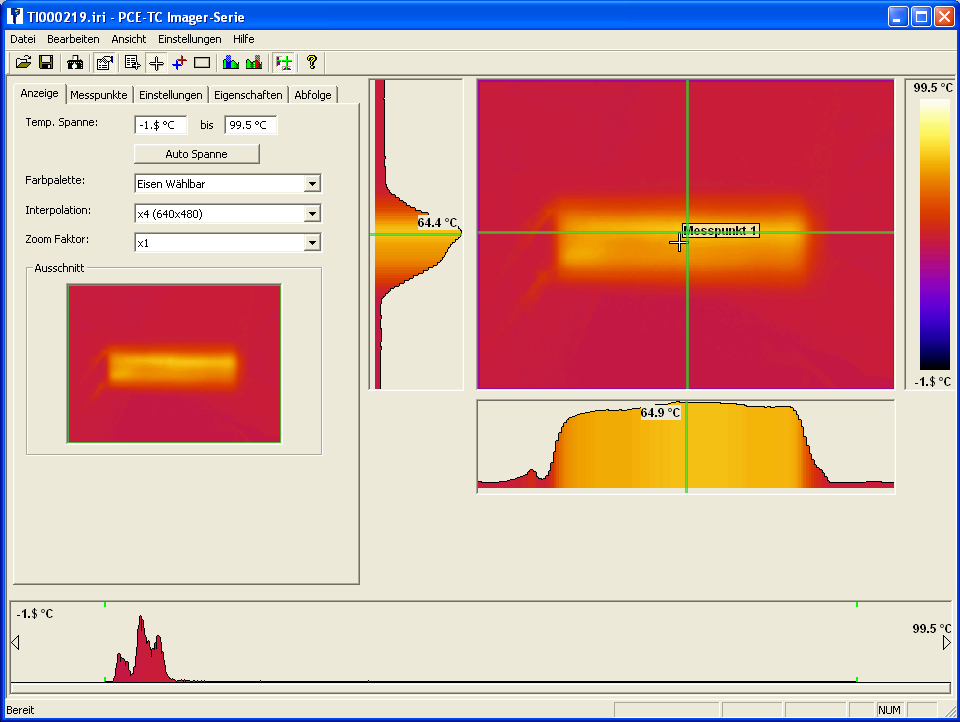

The heater layer provides an even and homogeneous heat-up process and self-regulating capabilities, preventing heater failure due to “hot spots” that can quickly develop with conventional heaters. This behaviour is attributed to the material’s light positive temperature coefficient (PTC). Materials with a PTC experience an increase in electrical resistance when their temperature is raised. Therefore the heat is regulated properly and the formation of hot spots, or an uncontrolled heat build-up are prevented. As a result, our heater layer can be designed to reach a maximum temperature for a given input voltage, since at some point any further increase in temperature would only be met with greater electrical resistance.

Another advantage is the coating’s smooth exhibition of distributed heating over the entire energized zone. Due to these self-limiting capabilities, on many occasions there is no need for thermal sensing of the heater, further reducing system complexity and still featuring full system safety.

Infrared Emission

Among other benefits, the Villinger heater layer offers high emission of infrared radiation heat. Infrared (IR) is a type of electromagnetic radiation that transfers heat to an object without the need of direct contact between the heat source and the object. This effect enables us to manufacture heating systems in such way, that the heater itself does not necessarily have to be in touch with the part or area to be heated.

Furthermore, the IR emission of the heater layer makes it the ideal solution for interior heating systems. Other than convection heat, IR passes through the outer skin and warms the human body directly from the inside, just like the warm-up process given by the sun. A much more convenient and efficient way of interior heating for car interiors, aircraft cabins and rooms of all kinds is guaranteed.

Note: If mainly contact heat is required, the heater can be manufactured in such way that contact heat is generated only.

Technical Parameters

Advantages:

- PTC effect: self controlling and works against hot spots

- Heaters safe by design – Heating systems with or without ECU

- High damage tolerance

- Low power consumption

- Flexible and easy application – Applicable to various base materials & shapes

- DO-160 approved (Aviation standards)

Technical Parameters:

- Coating Thickness: < 0,2mm

- Coating Weight: < 150g/m2

- Max. Temperature (active or passive): 180°C

- Max. Power Density: 120.000 W/m2

- Max. Input Voltage: 1000 Volts (AC or DC)